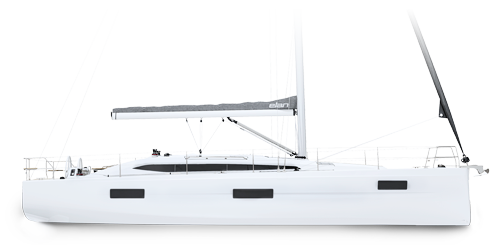

Elan technology

Elan Technology Interface

Welcome to Elan's technology interface. Please slide left or right to progress through points or click the middle button and pick from the menu.

Marine Standard Elan Bulkheads

Standard bulkheads used in our yachts are constructed of marine-grade plywood laminated into the deck, hull and inner structure to stiffen the yacht. It is the only way to ensure a good distribution of mechanical loads and is a requirement to lessen any kind of skewing or twisting of the yacht under pressure.

Available on:

E4

Impression 43

Impression 50.1

Composite bulkheads

A step up from the Marine Standard bulkheads, the composite version ensures an unbroken surface along the bulkhead and an equal distribution of mechanical loads along the cross-section. The vacuum-cured epoxy resin impregnated biaxial fabric takes the stiffness and durability to the next level and ensures the highest compact structure.

Available on:

Impression 50.1

E5

E6

GT Line

E4 Pure Performance

Vacuum Assisted Infusion Lamination

As the only sure way to prevent osmosis, and ensure uniform stiffness, lightness and safety the modern sailing yachts require, Elan was one of the first serial yacht manufacturers to adopt the Vacuum Assisted Infusion Lamination back in 2003. All Elan hulls are now produced through an advanced version of that VAIL technology. VAIL enables a complete saturation of epoxy resin and removes human error from the process.

How does VAIL work?

First step of the VAIL procedure follows the spray application of the gelcoat. Then, hand-application of the outer thin vinyl ester outer skin is applied to insure complete saturation and osmosis protection. This process is then followed by a careful layout of the multiaxial fabrics, PVC and SAN foam cores through a model-specific advanced laminate plan. After being hermetically sealed, the ISO NPG poly ester (or vinyl ester resin as an option) is pulled through a network of distribution tubes by a vacuum. The hull is then cured in a temperature-controlled environment to ensure perfect curing before the sealing is removed.

Benefits to the customer and environment

This VAIL process allows for weight gains up to 25% on composite parts and ensures considerable improvement of the hull’s mechanical properties. The “one-shot” nature of the process secures bonding between the fibers and the core, and thus reduces the possibility of laminate failure. It is a closed-mold process which negates the risk involved with volatility of organic compounds, drastically improving working conditions, industrial waste and protects the environment.

3D Vacuum Assisted Infusion Lamination

A step up from the VAIL process is the 3D VAIL technology. In essence, the 3D VAIL technology integrates inner yacht structure, stringers, and stringer supports (depending on yacht model) into the hull itself using vacuum-assisted infusion. When fully applied, this complicated and expensive process creates a one-piece laminated structure out of all load-bearing elements of the yacht, increasing the stiffness and lightness and ensures best mechanical properties. This converts into forward forces on the mast to fully convert into the forward momentum without energy loss. The 3D VAIL also represents the best possible seaworthiness of the yacht, as the whole interior acts like a single piece and can not be influenced by rough sea conditions.

VAIL TECHNOLOGIES BY YACHT:

VAIL hull: All Elan Yachts

VAIL deck: All Elan Yachts

3D VAIL hull, full: GT5, GT6

3D VAIL Stringers: E5, E6, Impression 43, Impression 50.1

3D Stringer Supports: E4

Hull and Deck Structure and Sandwich Laminate

Every Elan hull creation starts with the application the gelcoat, followed by a hand layup of highly saturated yet thin layer vinyl ester resin applied onto CSM. Intricate and yacht specific laminate plan is then applied to the hull, composing of coaxial and quadriaxial fiberglass, Corecell foam followed by vacuum assisted infusion of either poly ester or vinyl ester resin. Before separating from the mold, the hull cures in a temperature-controlled environment to guarantee the best possible hull form.

The vinyl ester outer skin ensures complete protection from osmosis, and the highly intricate laminate plan provides the best mechanical properties of the hull. Second only to carbon fibre hulls, Elan’s 3D VAIL sandwich laminate hulls are prime examples of the ultimate naval composite technology on the market.

Available on: On all yachts

U Shaped Keel Mounting Plate

Elan E Line and GT line are equipped with U profile keel mounting plates, especially designed to improve load distribution and prevents hull damage in emergencies. The stainless-steel backing plate is custom-made for each yacht.

Trapezoidal Pyramid Recessed Hull Keel Mount

Unique trapezoidal pyramid keel mount permits for seamless hull and keel fusion, facilitating best force transmission and increases the area of load distribution, ensuring a safer and more effective sailing.

Available on:

Elan E Line

Elan GT Line

Chainplates

Elan E line yachts and Impression 50.1 feature custom chainplates with backing-plate for optimum load distribution. The chainplates are positioned in-line with 3D VAIL stringers.

This results in a monolithic structure and increases safety and rigidity of rigging.

Elan GT line yachts feature custom chainplates with laminated backing-plate for optimum load distribution. The chainplates are positioned in-line with 3D VAIL stringers.

This results in a monolithic structure and increases safety and rigidity of rigging.

Elan Impression 40.1 and 45.1 yachts feature custom chainplates connected to inner hull via

Interior force distribution inox structure, increasing safety and efficiency of forces.

Impression 40.1

Impression 45.1

The chainplate attachment of the headstay is laminated to the starboard and port hull sides. The headstay is attached to plate and counter-plate with xx bolts.

all yachts

Elan Custom Design Rudder Blades

Elan’s special, in-house constructed rudder blades were designed by nautical architecture specifically for each yacht model. The unique composite rudder blades are a complete monolithic structure, optimized for rigidity, endurance, and lightness. Rudders are made with aluminum shafts for lighter construction (except Elan Impression 40.1 and 45.1).

Available on: All Elan Yachts

Active Chine Design and Hull Form Stability

Standing opposite the most modern chine designs which are included on yachts for aesthetics and internal volume, Elan chines are introduced in the hull geometry by Humphreys Yacht Design to introduce a better righting moment and allows the design to carry or share a lot of the righting moment requirements within the hull form itself. That results in moderation of the keel ballast weight and helps to drive displacement down and leads to a notable increase in the performance on the hull. The chined hull helps with the yachts tracking ability upwind and clean off the wake, giving the yacht improved speed and control downwind. When heeled at a perfect angle, the yacht attains an optimum underwater hull shape with a small wetted surface for minimum drag. The chines can also prevent broaching because they function as long skegs.

Available on:

Elan E Line

Elan GT Line

Computational Fluid Dynamic Testing

All Elan hulls were during the design process subjected to extensive Computational Fluid Dynamic testing, executed by the word-renowned Humphreys Yacht Design. Powerful hull geometries are famous for merging art and science; therefore, best hulls are created only by nautical architects with decades of experience and then extensively tested through CFD testing to fine-tune the design.

Available on: All Elan Yachts

Twin Rudder System

Due to wider and flatter hull design, twin rudders are more efficient; providing exceptional control and reduce the tendency to broach. The yacht does not stall easily, as her pitching moment is reduced. The twin rudder system provides finger-tip directional control, especially when heeled. It enables lighter loads on the helm and easier work for the autopilot. The rudder systems are independent and negate the need for an emergency tiller.

T Shaped Keel

The T-shaped keel lowers the centre of gravity and enables enhanced sail-carrying power, increasing speed and stability of the yacht.

Keel Stepped Mast

Enabling the most trimming options to an experienced sailor, keel stepped masts are a must-have feature on all E Line Elan Yachts and an integral part of rigging as defined by Humphreys Yacht Design. Keel-stepped masts also offer best safety, strength and security for sailing in challenging conditions.

Increased Beam

Increased beam optimizes form stability while enabling greater internal volume, space on deck and a stiffer feel under sail. A sophisticated hull geometry with more radius in the underwater hull sections aft is better balanced with fuller forward sections to increase beam without increasing drag.