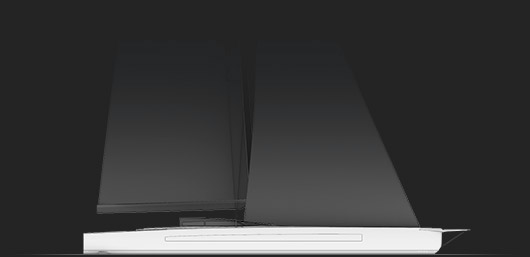

Technology Makes the Difference

For Elan, the project represents a return to the company’s most advanced tradition: using industrial efficiency in high-technology composite manufacturing to build genuine high-tech sailing yachts. History teaches us that important steps forward in performance were achieved by new technology developments. Advances from classical wood boatbuilding, to steel, to cold-molded resin-glued wood veneers, to glass-reinforced polyester and finally to carbon fibres with epoxy resin made the yachts lighter, stronger - and sailing faster. The carbon-epoxy platform provides a decisive strength-to-weight advantage and is the foundation of modern bluewater performance.